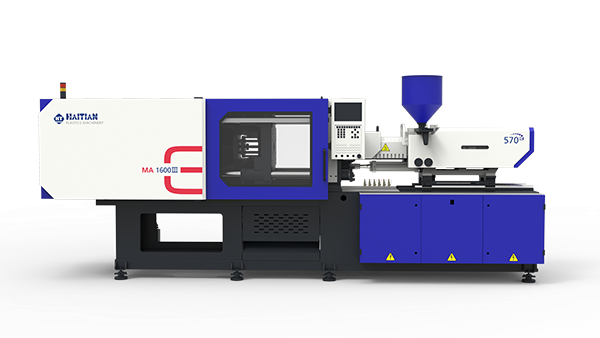

Haitian UK Stock Machines Available

Registrations open on 26th Feb for WorldSkills UK Industrial Robotics competition 2024

As part of its ongoing drive to encourage more young people to begin a career in automation and engineering, FANUC UK is inviting the country’s brightest young minds to take part in the WorldSkills UK Industrial Robotics competition. For the fourth year running, the industrial automation company is partnering with WorldSkills UK to give apprentices and students the chance to learn key robotics programming and operating skills with help from FANUC experts – and even earn the right to represent Squad UK at the international finals in China.

Entry is open at www.worldskillsuk.org/competitions/industrial-robotics from 26 February-29 March 2024 for teams of two people aged 16+. After completing an initial simulated entry-stage task, successful applicants will undertake training with FANUC ahead of the hands-on qualifier stage, which is being held at the Smart Factory Expo on 5-6 June at the NEC Birmingham. Visitors to the event will also be able to test their skills by taking part in a similar robotics trial alongside the competitors.

The WorldSkills UK Industrial Robotics competition reaches its peak in November when, following further training, the most talented teams will compete to programme and operate a robot in a real-world task at the National Finals during FANUC UK’s Open House event, held at its Coventry HQ. Winners will then be selected for Squad UK to compete in Shanghai in 2026.

“It’s crucial that the next generation is given the opportunity to explore the world of robotics and automation, to help nurture a passion that could lead to a future career path,” says Satty Cole, Business Development Manager for Education, FANUC UK. “Finding talented and enthusiastic students and taking them on the WorldSkills UK journey is immensely important to FANUC as part of our drive to support and train young people looking to consider a career in automation, and to bridge the current manufacturing skills gap. Gaining experience with real-world industrial robots and receiving hands-on training from current FANUC robotics engineers can help to ignite a spark in a young person that could last a lifetime.”

Peter O’Neill was part of the 2023 winning team and is keen to encourage other students to take part in this year’s competition: “You will learn new skills which could open future job opportunities. Participating in WorldSkills and qualifying for the national finals is something that will stand out on a CV.”

Ben Blackledge, Chief Executive, WorldSkills UK adds: “Skills will continue to be a key differentiator for business both at home and abroad and through our programmes we are working to ensure that all apprentices and students across the UK can gain access to high-quality technical education and apprenticeships that lead to real success for them and the UK as a whole.”

How to apply

Register in teams of two via the WorldSkills website www.worldskillsuk.org/competitions/industrial-robotics from 26 February 2024. Entries close on 29 March 2024.

Entry criteria

Eligible entrants are 16+ year old students in groups of two. Schools and colleges are encouraged to invite students to register, safe in the knowledge that FANUC will provide training and one on one support to the teams that make it through. There is no limit to the number of teams permitted to enter this competition per organisation.

Entrants must be present for the final stage of the competition at the National Finals in Coventry in November 2024. They must also be within a year of completion of a relevant Level 3 Apprenticeship and/or hold qualifications in an engineering-based subject to a minimum of a Level 3 or equivalent. Additionally, applicants must not have been employed within the industry of the chosen skill for more than three years prior to registration, not including the period of an apprenticeship.

The Passive Stage will require teams to complete a task on FANUC’s ROBOGUIDE system, which they can access using the 30-day free licence. FANUC will then provide everyone who makes it to the final with a free ROBOGUIDE educational license, to support their studies further.

Competition timeline

MedTech is a multi-billion-dollar manufacturing sector. Unsurprisingly, industry analysts are always keen to pinpoint the newest transformational medical and life science technologies that are expected to shape future treatment pathways.

Regional Medical Director of the Global Sumitomo (SHI) Demag team Andrew Sargisson shares his industry insight and global predictions for the medical market, touching upon how these latest trends are influencing investments in medical injection moulding facilities worldwide.

Thermoplastic and LSR moulding continues to be used extensively to manufacture a huge variety of everyday medical applications. The range is broad and can include implantable components, test tubes, petri dishes, PCR tubes, pipette tips and other labware, as well as medical monitoring devices, drug delivery components and surgical equipment.

In 2023, the global medical injection moulding market size was estimated at USD 22.54 billion[i]. It is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. Much of this growth is being driven by advances in self diagnostics, the home healthcare sector, improved healthcare infrastructures in emerging economies, and an aging population, which WHO predicts will double by 2050.

The medical market, particularly diagnostics, was strongly influenced by the Coronavirus pandemic. As anticipated, there has been a natural levelling-off for pandemic-related consumables.

More recently, there is a stronger leaning in the medical market towards larger strategic and more complex projects, such as drug delivery devices and pen style injectors. This is predominantly due to the global growth in diabetes care, where demand for advanced glucose monitoring and insulin delivery devices is propelling innovation. Testament to demand, credible industry reports forecast that the diabetes device market will surpass USD 68.2 billion by 2032, almost triple its 2022 value.

With regard to machinery, there is a strong move towards “copy & paste” systems and processes in both Europe and North America. The global medical team at Sumitomo (SHI) Demag, led by business development director Anatol Sattel, are also noting more requests for remote system access to historical machine data. This is predominantly to assist with troubleshooting and monitoring validated process settings.

To support these efforts, the company’s R&D team continues to develop an IoT dashboard to facilitate data analysis and visualisation, transfer and storage of know-how, as well as maintenance planning and prediction. Within this assistance system, additional autonomous and interconnected functions are being conceived to provide valuable insight into the machine performance and different production variables.

The development of process optimisation systems, integrating material and knowledge with simulation tools is probably the most exciting development on the horizon, claims Sargisson. Such systems will enable processors to observe advanced settings and capture deeper processing insights.

The company’s ultimate vision is an intelligent machine that can independently make predictions about part quality, machine wear and failures and deliver optimisations online. Enabling greater process consistency and allowing for real-time machine maintenance to be adjusted accordingly.

To support these advances and in order to meet the explicit quality management and validation ISO 13485 standards for medical devices, Sumitomo (SHI) Demag introduced new machine user parameters, digital quality control and KPI analytics into its IntElect S medical production package. One of these advanced Med-Spec demo cells is now located in Limerick, Ireland. This will enable customers to perform validations, run tool trials and use the facility to provide valuable process optimisation training to technicians.

Also observed during the pandemic, larger scale adoption of home healthcare and smart diagnostic devices, continues to accelerate at pace.

With significant access to start-up finding, telehealth is the boom-market to watch. It is current exhibiting a CAGR of 19.7% between now and 2030[ii]. Online video and audio consultations with physicians and medical consultants are increasingly being used to deliver quality healthcare while simultaneously reducing heavy work and cost burdens. The telehealth segment is split between services and products. Items such as wearable patient monitoring and telecommunication devices accounts for around one third of the market.

For medical moulders already producing vital monitoring devices, including oxygen, weight, glucose and ECG devices, as well as infusion pumps and cannulas etc. and already meeting the exacting healthcare standards, the transition to homecare device production should be relatively seamless.

High profile acquisitions of diagnostics companies, IPO listings, strategic partnerships, and the rise of virtual care platforms provide further assurance that the diagnostics market is on the cusp of another huge growth curve. This all indicates that there are clearly exciting opportunities ahead for moulders operating in the high tech medical device and diagnostics product development and production space.

In 2024, Sumitomo (SHI) Demag will host its inaugural productivity roadshow. With four stopovers planned for July in the UK and Ireland, including Limerick, customers will be invited to explore all the latest trends, productivity and profit-enhancing technologies. Including medical. Watch this space!

[i] Grand View Research, 2023 report, https://www.grandviewresearch.com/industry-analysis/medical-injection-molding-market

[ii] Telehealth Market to 2030, Fortune Business Insights https://www.fortunebusinessinsights.com/industry-reports/telehealth-market-101065

Could 2024 be the year that UK manufacturers finally embrace robotics? After trailing behind our international counterparts for years, the UK is now starting to catch up when it comes to the installation of industrial robotics. Across all sectors – from traditional automation users such as automotive and electronics to new adopters including food & beverage and logistics – manufacturing firms are breaking down longstanding barriers to automation, leading the International Federation of Robotics to predict ‘strong growth’ in the number of UK robot installations.

No longer seen as expensive, complicated or inflexible, today’s automated solutions are affordable, agile, easy to operate, and smaller than ever. And with the advent of smart features such as integrated vision systems and real-time energy reduction functionality, they are helping manufacturers to streamline their operations, increase their productivity and plug the labour gap better than ever before.

Here, seven experts from leading robotics manufacturer FANUC UK share their views on the hottest automation trends to look out for in 2024.

Energy-efficient solutions

“One of the major trends in automation is definitely energy efficiency. Aside from its primary function, a key requirement for any automation solution will be its ability to stabilise energy consumption and reduce it as low as possible. Being able to evidence this through live data monitoring and enhanced reporting will also be vital for any manufacturer serious about reaching net zero.”

Joe Mumby, Technical Sales Manager (ROBOSHOT)

Application-specific software

“I believe we’ll start to see an increase in bespoke application-specific software throughout 2024. This will not only make it easier for customers and system integrators when it comes to programming, but will also improve traceability compared to operations that are conducted manually.”

We’ve had a refresh! We’ve been a bit quiet lately as we’ve been busy updating our website to give it a fresh ‘new look’ enabling us to publish even more of whats happening in our industry!

If you have news or events you’d like us to add to our website just email us on pmmda@pmmda.org.uk

In the coming weeks we will be updating and adding data to our website, giving our members more access to industry information, buyers guides and technical info… watch this space!

We are delighted to welcome Shibaura Machine Co. Ltd c/o TM Robotics (Europe) Ltd as new members to the association, formerly known as Toshiba Machine, Shibaura will launch its new injection moulding machine offering at Interplas 2023. Welcome to the association and we very much look forward to working with you.

The UK’s No.1 plastics event, Interplas is set to take place at the end of the month, on 26-28th

September at the NEC, Birmingham.

This year’s event, a celebration of 75 years of Interplas and its forerunners, will see over 530 exhibitors

present on the show floor, alongside a host of conference sessions and features designed to elevate

UK manufacturing’s knowledge of the latest plastics technology from around the globe.

Just some of the exhibitors at the show include Arburg, Engel, Krauss Maffei, Wittmann Battenfeld,

Sepro, Mouldshop, TH Plastics, Bole, Summit Systems, Borche, Haitian, Motan Colortronic, Simoldes,

UK Extrusion, Negri Bossi, Billion, Piovan, Bausano, Ultra Polymers, Hasco, Distrupol, CMS, Fanuc, Albis,

Snetor, BMB Spa, Campetella, United Polymers and many more.

Duncan Wood, CEO of Rapid News Group, the organiser of Interplas, commented: “The £27 billion UK

plastics industry comes to Interplas to do business and with the largest number of exhibitors on the

show since 2002, Interplas 2023 will be an edition that befits a 75th birthday celebration.”

“There is a growing buzz across the industry, on social and in conversations that tells you Interplas is

around the corner. The show floor is going to be packed with innovation and visitor registration is

flying along well ahead of previous editions, if you are involved in any way in the plastics industry then

you have to be at the NEC at the end of the month!’

Ian Taylor, Managing Director for Conventions & Exhibitions at the NEC Group, said: “Interplas was one

of our very first shows at the NEC when we opened in 1976, so we’re delighted to see it go from

strength to strength as the UK’s definitive and leading plastics event.

“We’d like to wish everyone connected to Interplas a very happy 75th year, as we welcome this year’s

event to the NEC on 26th September.

“We know the event will facilitate valuable trading opportunities for hundreds of exhibiting

businesses, as the plastics industry comes together to showcase new products, machines and ideas.”

Exciting features visitors will gain access to include:

Interplas Insights Conference

A world-class conference programme will take place at the show presenting a wide range of themes

and challenges facing the plastics industry. With a new purpose-built theatre, top-calibre speakers will

take to the stage to present the latest in recycling, materials, digitalisation, regulation and much more.

There will also be an extensive line-up of interactive sessions during the conference, offering

attendees the opportunity to engage with influential speakers. Many of these sessions are led by

leading associations from the plastics industry. View the full conference programme here.

The Introducing Stage

This stage will host an exciting programme of inspiring speakers across the plastics sector. These

sessions are perfect for attendees wanting to find out the latest cutting-edge innovations in moulding

and forming, materials, automation, software, and inspection, to name just a few.

Knowledge Pavilion

The Knowledge Pavilion provides a rare opportunity for visitors to information-gather and network

among some of the most influential organisations in the British plastics industry. Representatives from

various groups, including RECOUP, the Polymer Machinery Manufacturers and Distributors Association

(PMMDA) and the Institute of Materials, Minerals and Mining (IOM3), will be on-hand to discuss R&D,

training, regulation and the future.

75@75

The plastics industry has undergone several transformations over the past 75 years. Throughout this

remarkable journey, certain individuals from the UK plastics community have been impactful in driving

change and innovation. To coincide with the 75th anniversary edition of Interplas, the organisers have

invited nominations of individuals who have made a significant impact to the UK plastics industry. The

75 names will be announced at Interplas 2023, followed by an evening of celebrations.

All-in-One Digital Platform

For 2023, visitors and exhibitors will get access to the new event hub and app, designed to improve

event experience and plan time efficiently. This smart technology will allow attendees to connect and

engage with the community, get personal recommendations using AI technology, and also schedule 1-

2-1 meetings with exhibitors and speakers.

Philip Law, Director – General of the British Plastics Federation, commented: “Interplas is the national

showcase for the UK plastics industry. If you’re serious about doing plastics in the UK, you’ve got to be

here.”

“The BPF is excited to be both exhibiting and moderating talks at the 75th anniversary of Interplas – a

show we have had a long relationship with. The BPF is celebrating an equivalent milestone this

year. It is our 90th anniversary. We encourage our members and all those with an interest in the BPF’s

activities to come and visit us during the show.” Philip Law, Director General, British Plastics

Federation.”

Thousands of companies have already registered for the event, such as JLR, McAlpine & Co,

Recipharm, L’Oréal, Dyson, Nissan, Aldi, BD, Kohler Mira, Caterpillar, Bentley Motors, Amcor, Tata

Motors, LEVC, Aqualisa and Lear Corporation

You can register for Interplas at interplasuk.com.

We’re excited to announce that UPM Conveyers have also joined PMMDA as members, a great big welcome and we look forward to working with you all.

RNA Automation have joined PMMDA, we’re really pleased that you’re on board and look forward to seeing you at future events.

Flegg Projects will be attending the Interplas plastics exhibition on September 26-28, 2023. Their Managing Director Jayson Flegg and Sales Director Mark Marshall invite attendees to visit Hall 4, Stand A90 to discuss your machinery transportation and installation needs.

With nearly 50 years of experience, Flegg Projects has the expertise to safely and efficiently move plastic moulding machines, extruders, and heavy equipment anywhere in the world. Whether you’re relocating across your facility or importing new machinery, they can handle your machinery move smoothly from start to finish.

Stop by and let them show you how their specialised equipment and skilled team can save you time and money on your next machinery move see how we do it

Plastic Machinery Movers – Flegg (fleggprojects.co.uk)