Demonstrating Digital Synergy to Ireland Market

SDUK Continues Learning Journey At PTIC

ENGEL Strengthens Global Presence Through Strategic Leadership Hires and Market

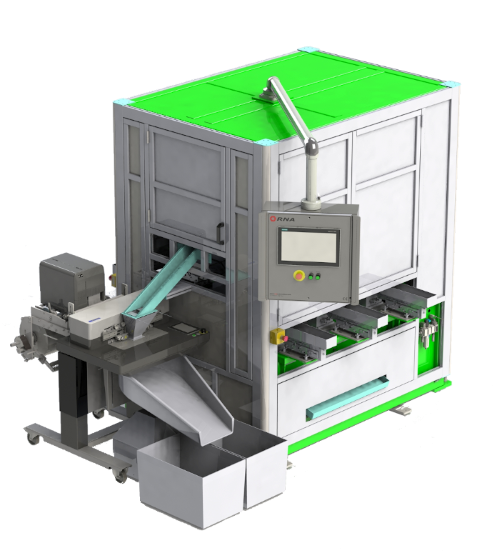

RNA Automation Ltd Introduces FlexType™ P Pack for Plastics Industry

Listgrove will be attending the K2025 show

FANUC to launch new ROBOSHOT SC injection moulding range at K 2025

High Maintenance For Low Maintenance

Future-Proof Production in Focus: Labotek Showcases Energy-Efficient Innovations at K 2025

Demonstrating Digital Synergy to Ireland Market

SDUK Continues Learning Journey At PTIC

ENGEL Strengthens Global Presence Through Strategic Leadership Hires and Market

RNA Automation Ltd Introduces FlexType™ P Pack for Plastics Industry

Listgrove will be attending the K2025 show

FANUC to launch new ROBOSHOT SC injection moulding range at K 2025