FANUC robot eases palletising bottleneck for salad dressing producer Brunos

By employing a 6-axis industrial FANUC robot to automate the palletising of its bottled salad dressing line, Swiss condiment producer Brunos has alleviated production inefficiencies, allowing the company to keep pace with its growing order book.

Founded in 2001, Brunos produces cooled salad dressings and gourmet butters. Since its inception, sales have risen steadily, prompting this progressive family business to employ increasingly sophisticated production methods to keep up with demand. Now a 45-employee enterprise, Brunos produces four million products each year at its 3,500m2 production facility in Sarnen, central Switzerland.

Although its production line was already automated, until recently, Brunos’ packaging and palletising function was still a manual process. This resulted in bottlenecks at the final stage of the process, as employees struggled to match the speed of the automated line. Unable to meet increased order levels and at the limit of its capabilities, the firm began to look for an alternative solution – but complex palletising patterns and limited space made their search a potential challenge.

“We had reached our limits,” explains Managing Director Michael Arnold. “By this point, we had two or three employees packing bottles manually into cardboard boxes, but they could hardly keep up with the speed of our production line. We began thinking about an automated solution for the palletising process, but our space was rather tight. We needed to find a solution with a compact footprint that would tie in with our existing automated processes in terms of quality and productivity.”

Fulfilling complex palletising patterns

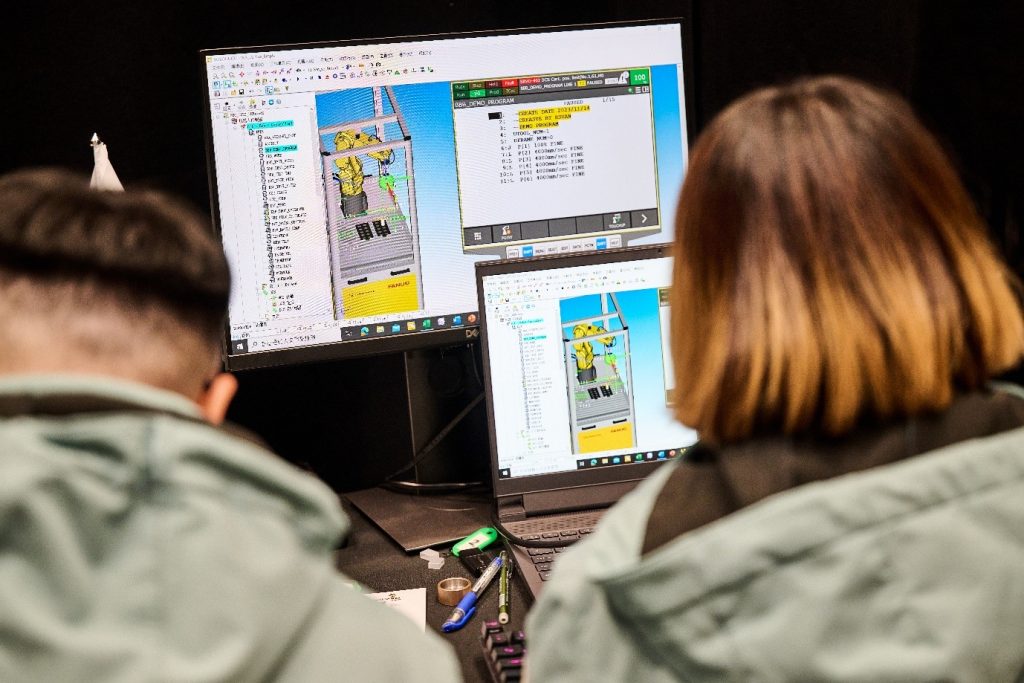

Brunos turned to Robotec Solutions AG, a local provider of robot-assisted automation, with more than 800 successful installations to its name across a diverse range of sectors. Jörg Lanz, Head of Sales at Robotec Solutions AG, says: “Working together with our customers, our most important task is to find the best automation solution for the application. In this project to palletise the bottled salad dressings, our main challenges were cycle time, space constraints and palletising patterns.”

With regards to the palletising patterns, Brunos’ production line fills bottles individually before placing them in groups of 6, 10 and 12. These groups then undergo shrink-wrapping in foil. “We needed to devise an innovative palletising pattern based on the pre-grouping of bottle packs and involving part-rotation,” reveals Jörg. “After completing each layer, we required the robot to place an additional intermediate layer on top. This operation would have to take place without changing the gripper to help minimise cycle time.”

Strong, long and lightweight

Robotec regularly leverages the quality of FANUC’s range of industrial robots and collaborative robots (cobots) to fulfil its customers’ requirements. In this instance, the ideal robot for the task was the strong, lightweight and compact FANUC M-710iC/50 6-axis industrial robot with 50kg payload and 2,050mm reach.

“It was clear from the start that we would choose a FANUC robot,” states Jörg. “We’ve been a FANUC partner for over 20 years and often say we have ‘yellow blood’ flowing through our veins. The FANUC M-710iC/50 fits Brunos’ requirements perfectly. Capable of carrying heavy loads, its long reach allows optimal processing of the palletising pattern – and always at full speed. Further plus points include low energy consumption, a small footprint and good availability of spare parts.”

Increasing capacity

For Brunos, automating its palletising function with the help of the FANUC M-710iC/50 robot has allowed it to keep pace with the production line, enabling the company to fulfil its ever-growing order book. Michael Arnold adds: “We are very happy with the results and success achieved following the introduction of the FANUC robot. It fulfils our expectations in terms of quality and productivity. We are completely satisfied.”

Check out the video here: https://www.youtube.com/watch?v=t9KOhG0ZYuM